Getting Started

Choosing to build your own piece of gear is a rewarding and great learning experience. If it’s your first time, this guide will walk you through the steps to complete your build. If you’re a grizzly old pro, you’re probably not even reading this!

Patience

Do you want to have a failed build and a huge headache? Rushing through the build and paying little attention to the instructions will result you in being sloppy with your soldering and assembly. As much as you want that cool new piece of gear up and running NOW, take your time and make sure to take breaks. Move through each step carefully, take pride in your build. A sloppy build, even if it's working, won’t give you the same sense of satisfaction as that of a good, clean, and neat build. Patience is key to the success of your build.

Tools

You’ll need a few basic tools to complete this build. Though this list may not be exhaustive, it’ll give you an idea of what you should have on hand.

- Soldering Iron It goes without saying that you need a soldering iron, get a decent one. At the very least you should have a 25-watt pencil style soldering iron. Weller sells the WP-25 for about $40 USD and it’s a solid entry-level soldering iron. Radio Shack sells a 40-watt model for about $10 USD. I’ve not used that model, but I bet it’s better than a lighter. If you’re going to build a few units and do some repairs, consider getting an adjustable temperature solder station. The Hakko 936 is a tried and tested unit that sells for about $70 USD. It’s a fabulous tool.

- Soldering Tip Most decent irons will allow you to insert different tip styles. For most PCB work, including this build, you’ll want a small chisel tip. I use the Hakko 936 iron with a D18-D16 tip. This is a 1.6mm radius chisel tip.

- Solder Solder is kind of like guitar strings in that you really need to feel which one is right for you. I went through a few types before I found one I liked. There are a few different considerations such as lead or lead-free, no-clean type, and the diameter. I use Kester #245 no clean solder. It's a 0.031” diameter 63/37 alloy. It needs no flux cleaning and is available at many local and online retailers (Part #24-6337-8800).

- Digital Multi-Meter (DMM) A good DMM is as important as a soldering iron. An auto-ranging DMM will make sorting resistors a breeze and help avoid time consuming errors. Testing and troubleshooting will make having a good DMM a must. An inexpensive model is better than nothing, but a good model will be a trusted tool on your bench and in your studio for years. It’s important to note that cheap meters generally do not measure AC (audio) level accurately above a few hundred Hertz at best. In audio we like to deal with 1KHz test signals, so get a nice meter. Fluke is the standard for DMMs. A Fluke 177 is another tried and tested workhorse. It’s not cheap, but it’s not that expensive for something you will use and depend on every day.

- Panavise Do you need a Panavise? No! Will it make your PCB stuffing much easier and make you look cool? Yes! These are not that expensive. Consider getting one.

- Pliers, Cutters, and Strippers A pair of fine needle nose pliers will come in handy for some of the final assembly work. I bet you already have a pair of these! Small diagonal cutters are a must. You’ll need these for trimming the component leads. Having a decent pair of wire strippers in the 16-26 AWG range is something you should have.

- Hex Key Set Also known as a Hex Wrench, Allen Wrench, and Allen Key. Whatever you call it, you need one to install the knobs. Consider getting a set with a nice storage case.

- Nut Drivers These are not as fun as they sound. These are used to tighten various nuts in assembly, including the faceplate components. Due to the length of the potentiometer and t-pad shafts, you’ll need a nut driver with a fairly deep channel. I used to use pliers to tighten these. I’d mare the nuts, scratch the panel and drop a few F-bombs. Do yourself a favor and get a Nut Driver set. I picked up a 7 piece set at a hardware mega-store for about $15.

Soldering Guide

Soldering WELL is one of those things that seems easy until you try it. Once you try, it starts to seem kind of difficult. Then finally you figure it out and it seems easy again.

Rather than trying to explain it to you, I went online, to find the best video tutorial I could. I settled on Dave Jones’ tutorial on the EEVBlog. Dave’s a wacky cat, but so are most guys who inhale lead all day. The tutorial is presented in three parts: tools; soldering through-hole components; and soldering surface mount components. For our purposes, I recommend you watch part 1 and 2. The videos are lengthy at about 25 minutes each, but they are well worth watching. Even I learned a few things.

The videos can be seen by visiting:

hairballaudio.com/eevblog-solder-tutorials

Theory of Operation

The Hairball Audio FET Compressor Kits and MNATS printed circuit boards (PCBs) are based on the famed UREI 1176 compressor designed by Bill Putnam in 1967. Prior to 1967 Putnam, like many, was using vacuum tubes for his preamp and compressor designs. The most famous of these may be the LA-2A optical compressor. The invention of the JFET in the early 1960s had Putnam thinking about other ways to design his studio equipment. The 1176 was conceived when he altered the 175/176 compressor to use a JFET as the gain reduction element. The compressor saw several revisions throughout the years but the design of the gain reduction stage remained mostly unchanged.

Basic Theory of Operation

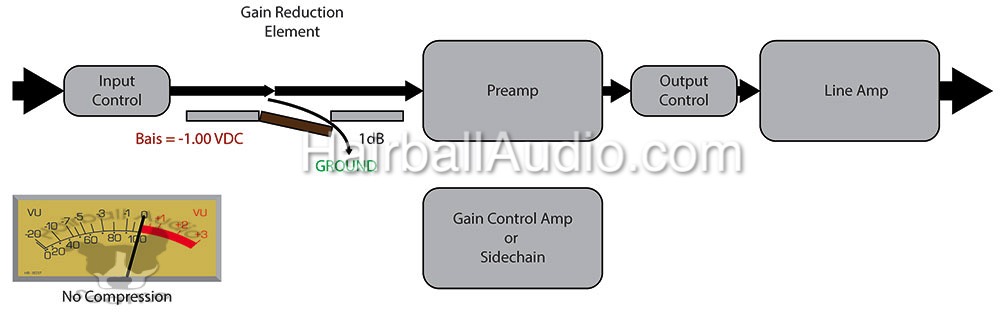

Before embarking on the build, let’s start by understanding the FET Compressor’s gain reduction design in the simplest terms. In the troubleshooting documents that follow later we’ll focus on the finer details. All revisions of the famed FET compressor utilize an N-channel JFET as a variable resistor to reduce or attenuate gain.

The signal enters the compressor through the input stage. For Revisions A through F this is a 600Ω T-pad attenuator and an input transformer with a small “step-down” ratio. In Revision G and later, the input stage is an IC opamp and 100KΩ potentiometer.

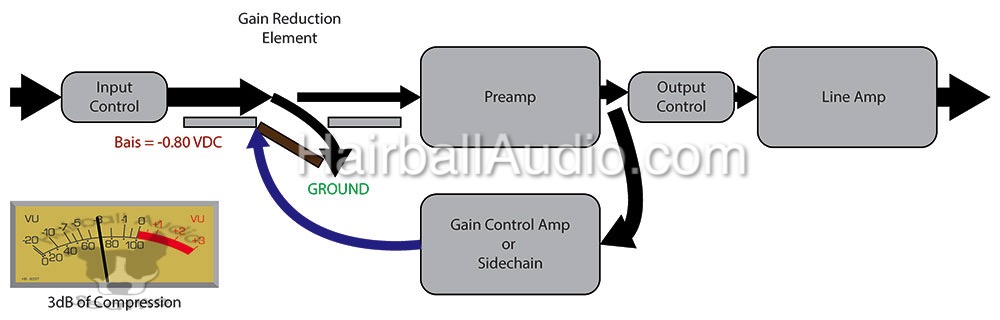

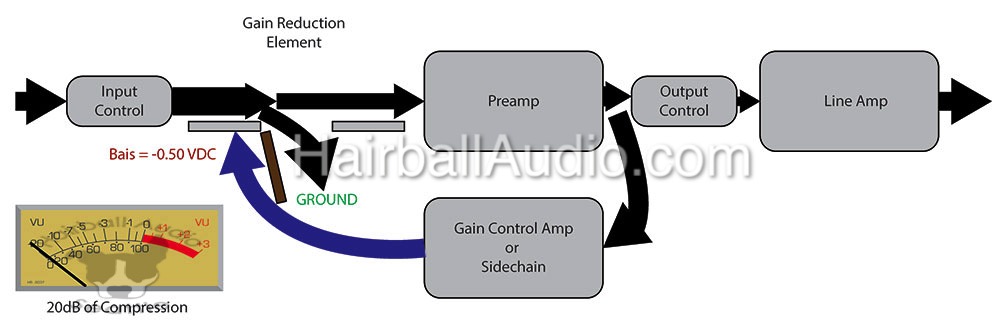

This input stage controls the gain of the preamp stage. After the preamp stage the signal meets a fork in the road. The signal is split and moves on to the output and the gain control amp. As you’ll see, the gain in this first stage also sets the gain reduction.

Let’s start by following its path through the gain control amp, we’ll address the output and line amp later. In the simplest terms, the gain control amp has one very important job - to convert the audio signal (AC) after the preamp stage into a DC voltage that can be fed back to the JFET gate. This DC voltage has a value in direct relation to the audio signal voltage. As the AC audio signal leaving the preamp increases, the resulting DC voltage will increase.

This resulting DC voltage will be used to control the JFET, which is set up like a variable resistor between the source and the drain. The audio signal passes along the top of the transistor at the source, and the drain is ultimately connected to ground either directly or through resistors (depending on the revision). The value of this JFET resistance determines how much signal is “dumped” to ground. If the value of the resistance is low, much of the signal will be shunted to ground and the signal that carries on through the circuit will be greatly reduced. If the value of the resistance is high, very little of the signal will be shunted to ground and the signal that carries on through the circuit will remain mostly intact. What controls this JFET resistance is the DC voltage that leaves the gain control amp and is fed back to the JFET gate. The N-channel JFET is biased with a negative DC voltage. When the voltage is more negative, the resistance is HIGH. As the voltage moves more positive, towards zero volts DC, the resistance is LOW. In the case of the 2N5457 used in this compressor, the resistance will reach its maximum (low GR) or “pinch off” at roughly -0.70 to -1.50 VDC. The resistance will be it’s lowest (high GR) at 0 VDC.

You know what everyone likes? Analogies! Let’s use one.

Think of the JFET as a trapdoor like shown above. The source is the area above the door, the drain is below, and the gate is the hinge of the door. Signals that fall through this trapdoor are lost in the abyss (or ground if you want to be technical). Like our JFET, this trapdoor’s hinge is set by a DC voltage. To start, we want to make sure that the trapdoor’s “default” position is set so that it can function properly. If the door is closed very tightly, the door may not swing open no matter how much DC voltage we feed back to it and we’ll never get gain reduction. If the door is left swung wide open by default, we’ll lose most of our signal all the time and we’ll be in constant high gain reduction. What we want to do is set the trapdoor so it’s almost completely closed but left open just a crack so it’ll swing open to any small change in DC. This setting is the most critical calibration point in the circuit. It’s called the Qbias.

I mentioned earlier that this Qbias or gate voltage sets the resistance highest at -0.70 to -1.50 VDC. Moving back to our trapdoor analogy, this means that the trapdoor is completely closed at -0.70 to -1.50 VDC. However, as I mentioned, we don’t want it completely closed; we want to leave it open a crack. For this compressor, it is designed so that the trapdoor is left open just enough so that 1dB is being lost or shunted to ground. That is the happy medium between having the door respond in the way we want, but not loosing too much signal before we even apply any gain reduction. This Qbias voltage is set in the Qbias calibration step and is somewhere around 90% of whatever the pinch-off (closed trap) voltage is for your individual FET. Because the pinch-off of transistors can vary widely and the Qbias is critical in the operation of the compressor, the Qbias must be calibrated for individual devices and cannot be globally set.

The image above shows the compressor with GR off. I’ve calibrated my Qbias and with a particular FET and I’ve ended up with a -1.00 VDC Qbias. Our trap door is set and we’re losing about 1dB to ground.

In the image above, gain reduction has been turned on. The input control now sets the level of gain in the preamp, which in turn affects the level of signal sent to the gain reduction amp. The larger this signal is, the more positive the Qbias will move, swinging the door open more. The Qbias is now more positive (-0.80 VDC) and we’re seeing about -3dB of gain reduction on our meter.

Now I’ve set the input control higher, which moves our Qbias even more positive -0.50 VDC and we’re seeing significant reduction nearing 20dB. In theory we would reach maximum gain reduction when the Qbias reaches 0 VDC. However, in reality we’ll never reach that; the distortion would be intolerable.

The one stage we have yet to address is the output control and line amp. Once we’ve reduced gain, the level may be too low for the next stage in processing. The output control sets the gain of the line amp or “makeup” gain.

Please note, the goal of this introduction is not to provide any values or instruction for calibration or troubleshooting, simply to provide a basic overview of how the FET compressor uses a JFET to reduce gain. We’ll get deeper into the compressor in the troubleshooting section, including ratio, attack, release, and threshold.

Enough of this nerd talk! Let’s talk about what we need to build this thing!